When purchasing chains for commercial use, many buyers tend to focus on getting a good price and don’t pay too much attention to quality. In this article, 3C Catene will explain how this thought does not always reflect reality. Based on the final application field of the chain, there are several characteristics to evaluate to avoid surprises after the purchase.

The welded chains produced by 3C Catene are subject to strict controls throughout the entire production process, from the choice of raw material to the surface finish. For this reason, they boast excellent functionality, reliability, and durability.

So, how to recognize a quality chain? Here are the five fundamental features to always take into account before purchasing any chain.

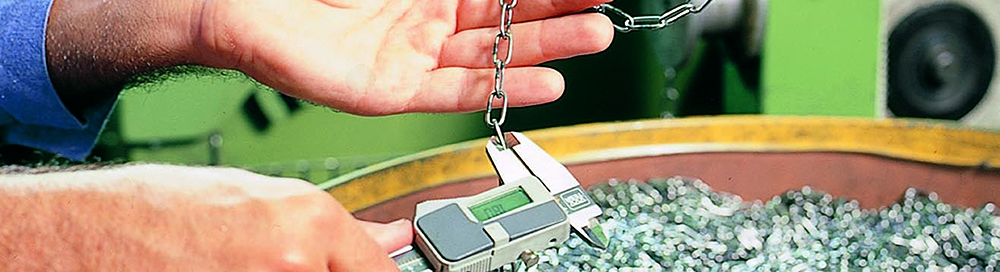

1. Link dimensions

The link dimensions (diameter, length, and width) must be declared and guaranteed. Often, there is the need to have objects pass through the link. Therefore, it is paramount that the dimensional tolerances reported in the catalog match the chain under examination.

2. Workload

Even though chains for commercial use, by their nature, are not subject to lifting or pulling, their workload must be specified. This way, the customer can correctly choose the most suitable chain based on the weight or the load to be supported.

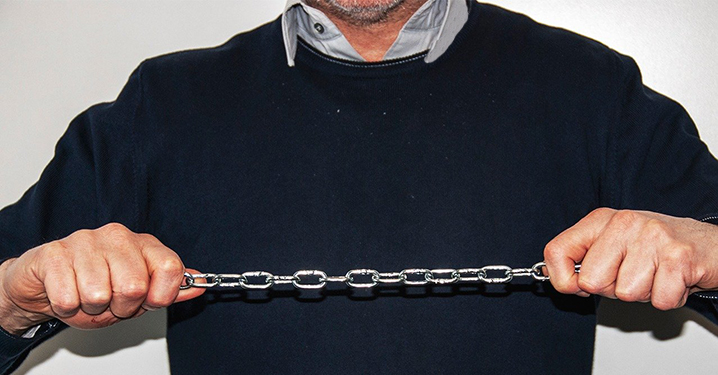

3. Welding

Welding directly influences the chain workload. The link must be well welded, but at the same time, it must be free of roughness. Both the tightness and shape design of the chain link must be guaranteed.

4. Link shape design

The link edges should be parallel, creating a symmetrical oval shape. The design also plays a huge role, especially in those fields of application that have both aesthetics and functional requirements.

5 The finish

A quality exterior coating (whether electrolytic galvanizing or painting) can be recognized primarily by two elements: a bright visual appearance, as well as a uniform coating thickness. The visual appearance gives the chain its aesthetic appeal according to personal taste and the application environment. The coating thickness, on the other hand, determines the resistance to atmospheric agents. To choose the most suitable surface finish, it’s important to know whether the chain will be used indoors or outdoors. For particularly aggressive environments, a hot-galvanized finish is preferable, or it must be made in AISI 304 or 31 stainless steel materials.